You must be signed in to read the rest of this article.

Registration on CDEWorld is free. You may also login to CDEWorld with your DentalAegis.com account.

With today's esthetic-minded patients, the dental industry is seeing a great level of interest in orthodontic aligners within all demographic groups.1 For these patients, it is all about an appealing smile, not just a white smile. Simultaneously, new hardware, software, and materials continue to be developed to make fabrication of aligners more realistic in dental laboratories that have not ventured into orthodontics previously (Figure 1 and Figure 2).

However, while the design and manufacturing processes may seem straightforward for dental and orthodontic laboratories, there is more to it than simply purchasing the CAD software and undergoing training. The FDA has specific regulations that need to be addressed before a laboratory begins fabricating orthodontic appliances for the first time.2 Be cautious, as not being FDA compliant regarding the manufacturing of aligners leaves your laboratory operating illegally and puts your production line in jeopardy of being shut down until the laboratory becomes FDA compliant.

What makes the aligner appliance different in the FDA's classification system than a mouthguard that is processed via the same steps? How can one device not require a 510(k) clearance when the other that appears to be identical has additional regulatory requirements? The FDA Device Classification Panel views each device's application and considers each device's indication prior to assigning a product code and classifications. For orthodontic aligners, the FDA recognized that the aligner is active and applying predetermined gentle directional force to orthodontically move the teeth: "This device moves the teeth by continuous gentle force for treatment of minor tooth malocclusion. … Digital scans of patient's dentition are used to create a series of plastic appliances which are intended to progressively move teeth."2 For that reason, it is a Class II device that requires a 510(k) clearance, a Quality System, and registration of the laboratory with the FDA. In the case of mouthguards that are simply protecting teeth and for which no treatment claims are made, the device does not require a 510(k) clearance or registration.3

Obtaining 510(k) clearance involves receiving an order, in the form of a letter, from the FDA finding the device to be substantially equivalent and stating that the device can be marketed in the US; this order "clears" the device for commercial distribution.4

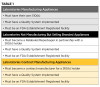

Options for Laboratories

Other pathways exist for a laboratory to enter the aligner market by associating with an aligner 510(k) holder. A laboratory can establish a Relabeler/Repackager relationship, whereby it either "packages finished devices... or repackages devices made by a manufacturer into different containers (excluding shipping containers)" or "changes the content of the labeling from that supplied from the original manufacturer for distribution under the establishment's own name."5 Basically, the 510(k) holder handles the manufacturing and private labels it for the laboratory. The laboratory handles marketing of the product, but the product is packaged and delivered as merely a "pass through" to the final client. A laboratory becoming a Relabeler/Repackager with a 510(k) holder still must have a Quality System implemented and must be an FDA Establishment Registered facility.5

The Relabeler/Repackager option is often a beneficial path to determine if a laboratory will be able to establish a client base of sufficient size to justify an investment in their own 510(k) clearance and bring the manufacturing in-house.

Another path is to establish a Contract Manufacturer relationship, whereby the laboratory "manufactures a finished device to another establishment's specifications."5 Basically, this is an agreement to manufacture the orthodontic aligners in the laboratory under the manufacturing instructions detailed in a holder's 510(k). Depending on the arrangement, the 510(k) holder may require financial considerations to act as a contract manufacturer. The arrangement is similar to the agreements that laboratories may have with sleep appliance companies that are 510(k) holders, where a laboratory manufactures and distributes sleep appliances that are branded.

It is the responsibility of the 510(k) holder to validate that the contract manufacturer's processes are following the detailed instructions in their 510(k). The contract manufacturer of the orthodontic aligner is to only use 510(k) cleared materials in their manufacturing processes and to validate and document in their Quality System that those 510(k) cleared processes are being followed. The contract manufacturer will also be required to be an establishment registered "Contract Manufacturer" with the FDA.5

Quality System and FDA Establishment Registration

In each of the above scenarios, the laboratory must operate under a Quality System and be appropriately registered with the FDA for both the establishment and the device.

A Quality System is an organized system of documents that are used to define the activities taking place in your laboratory that are assuring consistent quality and post-delivery market input such as customer complaints. "Manufacturers must establish and follow quality systems to help ensure that their products consistently meet applicable requirements and specifications. The quality systems for FDA-regulated products (food, drugs, biologics, and devices) are known as current good manufacturing practices (CGMP's)," the FDA says.6,7

Basically, these are standard operating procedures that "say what you are doing" to assure consistent quality of the devices. The next level is the Work Instruction that "states how you are going to do it" to assure the devices' consistent quality. Finally, the Quality Forms are where the laboratory documents "that you did what you said you were going to do." These Quality System documents and records are reviewed during audits to validate that the laboratory is saying what it does and how it does it, and to record that activities assuring quality are all in order and clearly support the manufacturing process, equipment, and materials. Laboratories should follow the FDA guidance that is provided in Title 21 CFR 820, detailing the Current Good Manufacturing Procedures.7

The FDA requires that laboratories that are involved in the production and distribution of some specific medical/dental devices intended for commercial distribution in the United States must register annually. This is referred to as Establishment Registration. Those establishments that are required to

register are also required to list the devices and the activities performed on those devices at that facility. These are referred to as Device Registrations. The important issue here is that most dental restorations that are hand manufactured fall under the dental laboratory FDA Establishment Registration Exemption (CFR 807.65(i)).8

A laboratory can choose multiple options from those outlined above, such as serving as both a Contract Manufacturer and a Relabeler/Repackager, and only pay one Establishment Registration fee. Additionally, that single Establishment Registration can cover other types of devices, such as custom milled abutments or sleep appliances, as long as each device is registered separately. Quality Systems are still required, as are either 510(k), Contract Manufacturer or Relabeler/Repackager arrangements. However, it is well worth taking advantage of the financial investment in the FDA Establishment Registration and incorporating other manufacturing processes that require FDA registration.

Conclusion

The public has a deep interest in this process, and many dentists' patients are inquiring about the treatment. Laboratories are getting inquiries from dentist clients regarding this service, and it is critically important that you have an understanding of how to provide the service legally, while being compliant with the FDA.

About the Author

Tim Torbenson

President

evo820

References

1. Weir T. Clear aligners in orthodontic treatment. Aust Dent J. 2017 Mar;62 Suppl 1:58-62.

2. Product Classification. U.S. Food & Drug Administration website. https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfpcd/classification.cfm?id=nxc. Updated April 19, 2021. Accessed April 21, 2021.

3. Product Classification. U.S. Food & Drug Administration website. https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfPCD/classification.cfm?id=1455. Updated April 19, 2021. Accessed April 21, 2021.

4. Premarket Notification 510(k). U.S. Food & Drug Administration website. https://www.fda.gov/medical-devices/premarket-submissions/premarket-notification-510k. Updated March 13, 2020. Accessed April 21, 2021.

5. Who Must Register, List and Pay the Fee. U.S. Food & Drug Administration website. https://www.fda.gov/medical-devices/device-registration-and-listing/who-must-register-list-and-pay-fee#domestic. Updated September 27, 2018. Accessed April 21, 2021.

6. Quality System (QS) Regulation/Medical Device Good Manufacturing Practices. U.S. Food & Drug Administration website. https://www.fda.gov/medical-devices/postmarket-requirements-devices/quality-system-qs-regulationmedical-device-good-manufacturing-practices. Updated September 27, 2018. Accessed April 21, 2021.

7. CFR - Code of Federal Regulations Title 21. U.S. Food & Drug Administration website. https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/CFRSearch.cfm?CFRPart=820. Updated April 1, 2020. Accessed April 21, 2021.

8. CFR - Code of Federal Regulations Title 21. U.S. Food & Drug Administration website. https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/cfrsearch.cfm?fr=807.65. Updated April 1, 2020. Accessed April 21, 2021.